Store Department

For a bulk production industry it is essential to maintain a well-organized & well equipped Inventory System. The main responsibility of this department is to store all the raw material necessary to produce garments. This department is sub divided into three sections.

Working Flowchart of Fabric Store Department:

They follow a strong and appropriate working procedure. Their work process flow is given below:

Working Procedure:

Receiving Fabric roll

Woven fabrics are supplied in roll package. Once these rolls of fabric are delivered the store in-charge receives the incoming consignment. This is the first phenomenon which is done in fabric store.

In-house Inventory

Once these rolls are received, the store in-charge matches the packing list of the fabric consignment with the original quantity of the fabric rolls (i.e. fabric width, fabric length). He also keeps the all the record in a log book. This inventory maybe done alone by the store in-charge or with the presence of a representative of the fabric supplier.

Cutting for inspection

At the time of inventory a piece of fabric is cut form every roll. The piece is of full width of the fabric and of a length depending on buyer (i.e. for H&M 22 inch of length, for others 12 inch of length). These cut piece is send for inspection tests like shrinkage, blanket making for shade segregation.

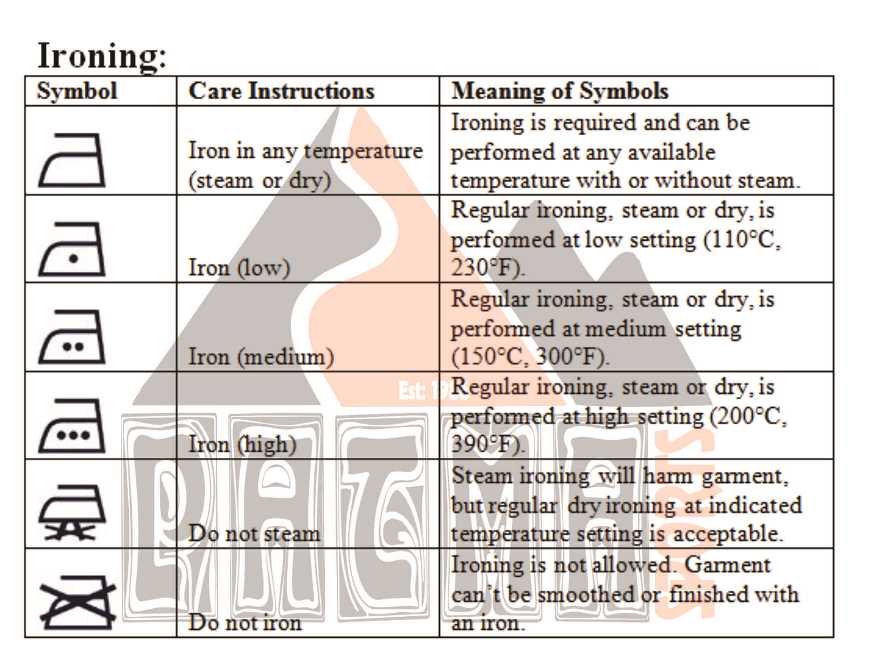

Care Label:

Care labels is a component or trimming of garment which contains some internationally recognized symbols that indicate the care instructions of the garment. These symbols are called care label codes.

History:

The care label was introduced in Europe about 1950. It’s a voluntary service so it was not regulated by any authority. It originated in The Netherlands and then spread to France and the other European countries as a voluntary service to the consumers offered by the textile and apparel industry. The care labeling code was protected by an international trademark, to control the correct application. The ownership of this international trademark belongs GINETEX, this International Association for Textile Care Labeling, has developed symbolic care labeling system in 1975.

International Standard:

ISO 3758 1991 provides a code of reference for the use of these symbols. The GINETEX care labeling system consists of five basic symbols for washing, bleaching, ironing, drying, dry cleaning and an extra symbol for wring. The symbols and their descriptions are shown in the following.

Notes: